The development of technology allows FEMALEDENTISTRY to be made, thus also meeting the high aesthetic demands of patients.

But what are they made of if not metal?

IPS e.max is a new innovative all-ceramic system.

A highly aesthetic material with extreme load-bearing properties, fully covering all indications of pressed ceramics from thin shells to longer bridges.

What exactly are we talking about?

Up to now, when we planned to make ceramic work in dentistry, we always needed a base (usually metal) on which to layer the covering material, in this case porcelain. This was done by the master dental technician, layer by layer, using a tiny brush to create the shape of the future tooth. The finished substitute was fired in a kiln, making the ceramic hard and shiny. Several problems have arisen from this technique. On the one hand, it was aesthetic: covering the dark metal with light porcelain could not perfectly reproduce all the essential qualities of the original tooth. The other problem is the difference between the two materials. The metal-ceramic interface has always been a weak point for metal-ceramic replacements made in this way. The porcelain cracked easily, and over time the metal peeked out from under the chipped material.

This was changed a few years ago by the introduction of zirconia (ZrO2) ceramics, which resulted in a stronger frame than metals, but with a matte milky white base colour, allowing for more aesthetic solutions.

What has changed?

The system developed by IvoclarVivadent has innovated in every existing area. Each one is compatible with the other, can be bonded together with very high strengths, has a very high load capacity, wear resistance, durability and, last but not least, aesthetics without metal. There are basically 3 types of ceramics and 3 production technologies.

Materials:

- Lithium disilicate glass ceramic – The perfect combination of aesthetics and strength. It can be used for both anterior and posterior restorations, mostly for single tooth restorations. These include crowns, shells, inlays, onlays.

- Zirconia ceramic – An excellent solution for larger restorations in lateral areas subject to increased chewing forces. Longer bridges, crowns can be made. It can be covered with layered ceramics, pressed ceramics and CAD technology.

- Fluorapatite glass-ceramic – Choose any framework for any indication area, the option is given to have it fully customized by the master dental technician using the traditional layering technique.

Technology:

IPS e.max CAD

CAD/CAM – Computer aided design and manufacturing is the Hungarian equivalent of this English term. The idea is that an impression of a tooth prepared by the dentist is first digitised in the dental laboratory using a high-resolution 3D laser scanner. Then, a design program is used to plan the restoration, which can be a crown, bridge, bridge framework, inlay, onlay, partial crown or shell. After the design is complete, the machine, again under computer control, sculpts the semi-finished work from a block. It is then fired in a kiln to achieve the desired hardness. The blocks come in a variety of colours, but if required after firing, the dental technician will custom stain the replacement to achieve the ultimate high aesthetic.

IPS e.max Press

Pressing-The design and preparation is very similar to the previous process, the difference is that in the final stage the machine does not carve the finished product from a block, but the liquid ceramic mass is pressed into a mould under high pressure. After it has set, the master dental technician cuts it off the casting pin and works out the final shape. If necessary, you can also have the work painted individually.

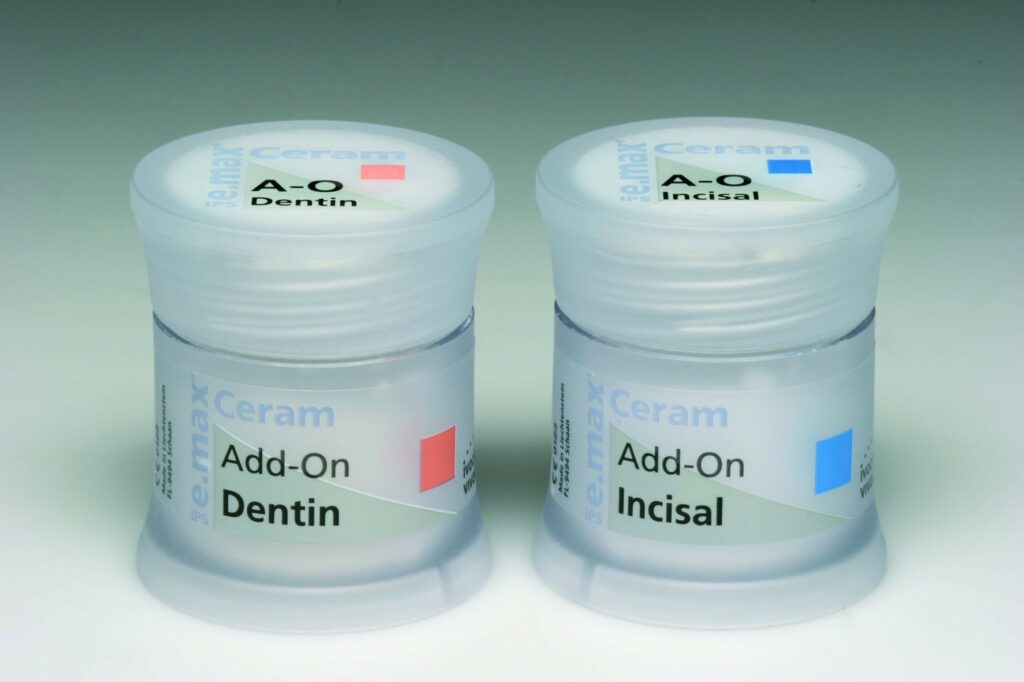

IPS e.maxCeram

Layering-Just to complete the product range, Ivoclar has created a ceramic based on the traditional layering technique. Fully compatible with the materials listed above. The purpose is that if any touch-ups are required on the carved or chiselled work, the dental technician can use a brush to make the desired shape in the traditional way.